R&D 100 Awards

R&D 100 Awards

Since 1963, R&D Magazine has honored inventors by identifying the 100 most technologically significant products and advancements for each year and recognizing the winning innovators and their organizations. Pacific Northwest National Laboratory (PNNL) received six R&D 100 Awards in FY20, and a total of 116 since we began submitting entries in 1969. You can see these winners by clicking on any of the years listed here. For more information on PNNL's R&D 100 Awards, contact Paul Runci.

Years

2022 | 2021 | 2020 | 2019 | 2018 | 2017 | 2016 | 2015 | 2014 | 2013 | 2012 | 2011 | 2010 | 2009 | 2008 | 2007 | 2006 | 2005 | 2004 | 2003 | 2002 | 2001 | 2000 | 1999 | 1998 | 1997 | 1996 | 1995 | 1994 | 1993 | 1992 | 1991 | 1990 | 1989 | 1988 | 1986 | 1984 | 1983 | 1982 | 1974 | 1972 | 1969 |

2022

MOSAICS — Alysha Johnson, Shawn Hampton, Lyndsey Franklin, Scott Dowson, Josh Kolasch, Sebastian Ang, Keith Thornhill, Terri Merz, Mark Hadley, Sam Clements

MOSAICS is the first-ever comprehensive, integrated, and automated cyber defense capability for industrial control systems. MOSAICS is a comprehensive, integrated, and automated solution that allows system operators to more quickly, easily, and effectively detect and characterize cyberattacks against critical infrastructure systems in real-time. Eventually the tool will provide support for automated response actions. MOSAICS is the winner of an R&D 100 Award in the Software/Services category. The lead developer of the tool was Johns Hopkins University Applied Physics Laboratory, with Pacific Northwest National Laboratory, Sandia National Laboratories, and Idaho National Laboratory as co-developers.

2021

Lab-on-a-Fish: Daniel Deng, Jun Lu, Yang Yang, Brett Pflugrath, Huidong Li, Jayson Martinez, Jie Xiao, Bingbin Wu, and Mitchell Myjak

Lab-on-a-Fish is a miniature biosensor that monitors and evaluates the health, behavior, and environment of fish in real time. It allows scientists to study fish, marine animals, and birds to understand human impacts on ecosystems. The Lab-on-a-Fish technology is the world’s first to combine edge computing—data processing by the device itself—with wireless acoustic sensing to assess animal behavior, physiology, and environment. Using an array of sensors, ecologists can study small species for longer durations than have been possible with other technologies.

ThermalTracker-3D: Shari Matzner, Rodrigo Guerrero, Ryan Hull, Tom Warfel, and Nolann Williams

ThermalTracker-3D helps determine if birds and bats are flying at heights where they risk colliding with turbine blades. The technology tracks avian flight activity at remote locations under study for offshore wind development. It is the only technology to use stereo vision to capture 3D flight tracks of small to large animals, providing critical information (e.g., wingspan, flight height, and overall speed) day or night and in all weather conditions. Data captured using this tool helped lead to expedite and simplify costly environmental permitting.

Shadow Figment: Thomas Edgar, William Hofer, Draguna Vrabie, Katy Nowak, Garret Seppala, and Juan Brandi-Lozano

Shadow Figment software uses interactive decoys mapped to real devices to defend critical infrastructure and systems against cyberattacks. Typical targets of attacks include buildings, the electric grid, water and sewage systems, and pipelines. The decoys convince attackers that they are making progress by sending real-time and plausible response signals. With the attacker safely preoccupied, Shadow Figment alerts defenders of the threat and gathers information to respond appropriately without affecting system performance.

2020

Millimeter-Wave Shoe Scanner — Mark Jones, David Sheen, Ryan Conrad, Trevor Clark, Maurio Grando, Thomas Hall, Trent Hartman, Michael Larche, Elvin Munoz, Stan Owsley, Rob Stahl, and Jonathan Tedeschi (PNNL); Brian Hatchell and Doug McMakin (PNNL retired); John Fortune and Brian Lewis (DHS S&T)

The Millimeter-Wave Shoe Scanner, which uses imaging to detect concealed objects in footwear, could potentially be integrated into the floor of a body-scanning portal at airports. Anyone who travels can recognize the potential benefit: Passengers would not need to remove their shoes to pass through airport security, thus reducing a bottleneck in screenings. PNNL partnered with the U.S. Department of Homeland Security Science and Technology to build the shoe scanner. The scanner builds on PNNL's pioneering research in optical and acoustic holography dating back to the 1960s. Scientists and engineers determined how to use millimeter waves to penetrate clothing and scan for concealed objects, resulting in commercial body scanner systems.

Self-Healing Cement - Carlos Fernandez, Phillip Koech, Jaehun Chun, Vanda Glezakou, Nicolas Huerta, and Manh-Thuong Nguyen (PNNL); Wooyong Um (Pohang University of Science and Technology); Kenton Rod (Washington State University)

A winner in the R&D 100 Mechanical/Materials category, the Self-Healing Cement can repair itself when cracked or damaged within 24 hours. The innovation also was bestowed a silver medal for the R&D 100 Award Green Tech category. PNNL’s self-healing cement has a restorative polymer component that migrates toward cracks, rebonds, and heals fractures fully restoring its mechanical integrity throughout the lifetime of the material. The polymer makes the material flexible further reducing fracture creation and propagation, unlike conventional, brittle cement. Cracking is a common, expensive problem with cement and concrete, with an annual price tag for repairs of $18 billion to $21 billion. Cracked cement is a persistent problem for the oil and geothermal industries, which uses the construction material to build subsurface wells.

Rapid Analytics for Disaster Response - Andre Coleman, Kyle Larson, Jerry Tagestad, Tim Seiple, Grant Fujimoto, and Jim Spracklen (PNNL)

Rapid Analytics for Disaster Response (RADR), software that can quickly assess an array of post-disaster damage from hurricanes, floods, tornados, wildfires, and earthquakes, earned an R&D 100 Award in the Software/Services category. PNNL researchers developed RADR as a software suite that provides disaster managers, first responders, utilities, energy providers, and others with a damage assessment capability using image analytics. The software disseminates analytics to a cloud-based platform within six to eight hours of an event— three to six times faster than traditional methods.

Shear Assisted Processing and Extrusion – Curt Lavender, Vineet Joshi, Glenn Grant, Saumyadeep Jana, Jens Darsell, Scott Whalen, Nicole Overman, Reza Rabby, Aashish Rohatgi, Mageshwari Komarasamy, Keerti Kappagantula, Darrell Herling, and Xiao Li (PNNL)

Shear Assisted Processing and Extrusion (ShAPE™), an energy-efficient manufacturing method that transforms and improves metals, earned an R&D 100 Award in the Process/Prototyping category. ShAPE™ changes metal feedstocks— such as ingots, powders, or recycled scrap—into higher performing components in a single step. ShAPE™—a PNNL custom-designed machine—uses less energy than conventional extrusion and delivers better products, enabling next-generation materials for a wide variety of high-tech industries.

Amanzi–ATS

PNNL shared an R&D 100 Award with lead developer Los Alamos National Laboratory for the mapping software application, “Amanzi–ATS: Modeling Environmental Systems across Scales.” In addition to PNNL, Oak Ridge National Laboratory and Lawrence Berkeley National Laboratory shared in the software’s development.

2019

Xenon International – James Hayes, Mark Panisko, Matthew Cooper, Warren Harper, Tim Stewart, Charles Hubbard, Mike Ripplinger, Matthew Covert, James Ely, Paul Humble, Dan Keller, and Anthony Day (PNNL); Michael Howard, Aaron Orr, Tricia Gomulinski, Carissa Helmreich, Robert Mikuylak, Kevin Carter, and Paul Brown (TBE)

The ability to accurately detect nuclear explosions is a key component of national security and international treaty monitoring. Xenon International, a fully automated radioxenon monitoring system developed by PNNL and Teledyne Brown Engineering, drastically improves existing national and international radioxenon monitoring capabilities by doubling the sensitivity of today’s systems. Xenon International works by collecting, separating, purifying, and quantifying radioxenon isotopes to continuously monitor for radioxenon evidence from underground nuclear explosions. The system’s technology—a pairing of national laboratory expertise in nuclear detection science and technology with commercial engineering and manufacturing capabilities—could revolutionize the collection and detection of radioxenon in the field.

MLSTONES – Elena Peterson, Christopher Oehmen, Darren Curtis, Aaron Phillips, Keith Star, and Richard Griswold (PNNL); Zach Beech (former PNNL)

Malware is an increasingly prevalent cyberthreat for consumers, businesses, and government agencies. In response to these threats, PNNL developed MLSTONES, which stands for Machine Learning String Tools for Operational and Network Security. This one-of-a-kind malware detection tool identifies never-before-seen malware—something other detection tools can’t do. Like the evolution of DNA passed down through generations, software is frequently built from reused pieces of code. Adversaries create zero-day attacks by modifying existing malware to bypass traditional detection tools. Borrowing from biology, MLSTONES converts software code into DNA-like structures and identifies code that contains similarities with known malware. This building-block approach makes it difficult for attackers to evolve malware that evades detection and gives cyber analysts a head start in understanding the intent of the malware. MLSTONES offers a new level of protection for critical infrastructures and defense against large-scale, debilitating cyberattacks.

VaporID – Robert Ewing, David Atkinson, Brian Clowers, Blandina Valenzuela, and Elizabeth Denis (PNNL)

Dangerous chemical compounds that are transported to the United States threaten our health, safety, and security. VaporID, a vapor-sampling device developed by PNNL, is a disruptive technology that enables the detection of narcotics and explosives down to the parts-per-quadrillion level in ambient air. It works in seconds, and unlike canine teams, it never tires or gets distracted. The technology detects explosives and narcotics simultaneously and can be integrated with existing visual scanning systems. Unlike current, less-accurate, more labor-intensive, and lower-throughput technologies, VaporID can also be deployed in dirty environments. The technology is noninvasive and needs no expensive materials or radioactive sources to function. VaporID’s low operating costs, automatic configuration, and quantified results increase confidence in screening decisions for passengers, mail, or cargo. In 2020, the technology was named Invention of the Year by GeekWire, the Seattle-based technology news company.

2018

Protecting the electric grid — DCAT![]() - Nader Samaan, Jeff Dagle, Yuri Makarov, Ruisheng Diao (formerly PNNL), Yousu Chen, Qiuhua Huang, Renke Huang, Xinya Li, Laurie Miller, Tony Nguyen, Frank Tuffner, Mallikarjuna Vallem, Bharat Vyakaranam (PNNL)

- Nader Samaan, Jeff Dagle, Yuri Makarov, Ruisheng Diao (formerly PNNL), Yousu Chen, Qiuhua Huang, Renke Huang, Xinya Li, Laurie Miller, Tony Nguyen, Frank Tuffner, Mallikarjuna Vallem, Bharat Vyakaranam (PNNL)

Ever-increasing cyberattacks and natural disasters can wallop the nation's electric grid, potentially causing cascading power outages that cost utilities and their customers billions of dollars. PNNL's answer for minimizing the impact of extreme events on power grid is DCAT. By simulating thousands of extreme events, DCAT automatically meshes the evaluation of steady-state operations with changing occurrences in the electric grid to find weak spots. Once a weakness is identified, DCAT determines the impacts that would result from a cascading power outage and provides the power operator with actions to stop the outage before it happens. With DCAT, utilities would gain at least 50 percent in efficiency for analyzing grid occurrences compared to today's more manual processes.

Shifting cybersecurity from reaction to preemption — StreamWorks![]() – Sutanay Choudhury, Khushbu Agarwal, Sherman Beus, George Chin (PNNL); Vivek Datla (formerly PNNL); Lawrence Holder (Washington State University)

– Sutanay Choudhury, Khushbu Agarwal, Sherman Beus, George Chin (PNNL); Vivek Datla (formerly PNNL); Lawrence Holder (Washington State University)

One hundred forty six days — that's how long, on average, it takes to detect a cyberbreach from the time it begins. PNNL's StreamWorks cuts that time significantly — to near real-time — by detecting emerging patterns of sophisticated cyberattacks in massive data streams. Combining several analytic approaches, never before seen together in a cybersecurity tool, the technology tells a cyber analyst when major suspicious patterns are occurring, along with a description of the potential threat and a rationale for why the threat was selected — so the analyst doesn't have to guess, but instead can take action swiftly.

2017

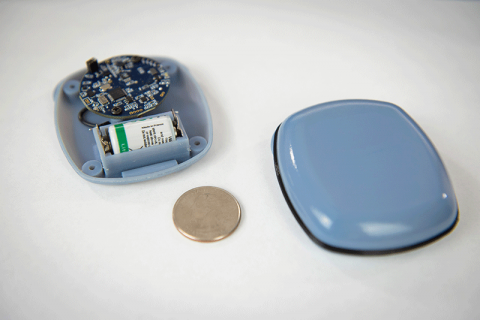

Acoustic Gunshot Detection System - Jim Skorpik, Eric Gonzalez, and Michael S. Hughes (PNNL).

Active-shooter detection systems are generally designed for outdoor, urban environments. But now, researchers at PNNL have created a gunshot detector specifically for indoor environments, such as schools and public buildings. The small, inexpensive device is battery powered and can connect wirelessly to existing security systems. It can distinguish between gunshots and other sounds. SecurityUSA Services has licensed the Acoustic Gunshot Detector for integration into its lockdown and reporting systems. With SecurityUSA's version of the sensor, once a shot is detected, its system can activate a building lockdown and notify authorities.

Multibed Adsorption Recuperating Cooling – Pete McGrail, Radha Kishan Motkuri, and Jeromy Jenks (PNNL); Brett Van Horn (Arkema).

A new class of solid-state cooling technology that operates on wasted heat from power sources such as generators could lead to significant energy and cost savings in homes, buildings, cars, trucks, and industrial processes. Currently, most air conditioners use tremendous amounts of energy. In fact, 15 percent of U.S. energy usage goes towards cooling. PNNL has incorporated a proprietary nanomaterial into a new cooling system, which uses heat to drive the cooling process instead of electricity. Traditional adsorption coolers are too large, heavy, and expensive to use in most situations. In contrast, MARCool is half the size and twice as efficient as standard adsorption chiller systems. In addition, many of its components are already commercially available and it works with standard refrigerants on the market. MARCool, which stands for Multibed Adsorption Recuperative Cooling, was developed by PNNL and Arkema Inc.

Friction Stir Scribe Process for Joining Dissimilar Materials – Piyush Upadhyay, Glenn Grant, Karl Mattlin, Saumyadeep Jana, Scott Whalen (PNNL), Yuri Hovanski and Rich Davies (former PNNL staff).

To reduce fuel consumption, U.S. automakers are incorporating lightweight materials into new vehicles. But manufacturers using conventional processes, such as welding, can't join dissimilar materials with different melting points without sacrificing strength, durability or safety. PNNL's Friction Stir Scribe Process addresses this challenge. It is the first technology that makes it possible to join materials with drastically different melting points in a continuous, linear, or curved manner without needing additional adhesives, bolts, and rivets. Using this tool, manufacturers can now incorporate new and different materials into a variety of strong, lightweight parts, such as sub-frames for the engine chassis, without sacrificing strength or durability. See video![]() .

.

Ircell – Markus Geiser, Markus Mangold, and Andreas Hugi (IRsweep); Bruce Bernacki (PNNL).

Scientists need to rapidly identify trace gases when detecting toxic industrial chemicals, identifying disease indicators, or monitoring for possible proliferation of nuclear or chemical weapons. Current approaches don't always provide the measurement sensitivity and resolution needed to detect tiny amounts of toxins hiding among larger volumes of more benign gases. PNNL's compact, patented IRcell technology is a dramatic improvement to traditional detection methods. Compared to current technologies, its design provides greater sensitivity and speed. In addition, it requires only a tiny sample volume for analysis and is compact enough to be used in the field. IRcell has been licensed to IRsweep, a provider of high-performance mid-infrared sensing solutions. See video![]() .

.

SerialTap – Thomas Edgar, Sean Zabriskie, and Eric Choi (PNNL).

Most cybersecurity tools and methods are highly sophisticated, designed to protect critical data from attackers around the globe. But some older industrial control systems, such as those that manage the operation of transportation systems and the delivery of water and electricity, cannot interact with today's cybersecurity tools. SerialTap, created by PNNL, is designed to protect these legacy systems. The palm-sized device is an inexpensive, non-intrusive add-on that can monitor and verify the activity in older serial communication systems. A startup company, Cynash, licensed the technology and is commercializing it. See video![]() .

.

Structures for Lossless Ion Manipulations – Richard D. Smith, Ian Webb, Sandilya Garimella, Yehia Ibrahim, Erin Baker, Randolph Norheim, Spencer Prost, and Raymond Dunn (PNNL); Liulin Deng, Ahmed Hamid, and Gordon Anderson (former PNNL).

Medical researchers need to be able to quickly distinguish and measure different molecules in biological samples such as blood. But standard analytical technologies are slow, cumbersome, expensive and, too often, ineffective. As an example, they can't always distinguish between molecules with similar masses but different structures. PNNL's Structures for Lossless Ion Manipulations (SLIM) technology is 1,000 times faster than current methods and can identify trace differences in samples as small as a single cell. A startup, MOBILion, is commercializing SLIM, with the goal of creating a compact version that doctors could use to provide biomarker-based disease results to patients. See video![]() .

.

National Risk Assessment Partnership Toolset – Nomination led by National Energy Technology Laboratory, PNNL team members: Christopher Brown, Amanda Lawter, Catherine Yonkofski, Chris Murray, Diana Bacon, Jason Gastelum, Kirk Cantrell, Nik Qafoku, and Luke Rodriguez (PNNL); Ellen Porter and George Last (former PNNL).

Deep underground geologic formations offer promising places to safely and effectively store large volumes of carbon dioxide generated from burning coal, oil, and natural gas. The NRAP Toolset is the first complete suite of computer software that models possible environmental risks from potential storage sites, such as fluid leakage and earthquakes. The toolset draws on the expertise of five DOE national laboratories, including PNNL, and is being used by over 250 stakeholders from academia, regulatory agencies, and industry.

2016

E4D-RT: Real-time Four-Dimensional Subsurface Imaging Software – – Timothy C. Johnson

Much like medical scans, a new technology allows users to remotely look into the Earth's subsurface in real time. Contaminants in soils often provide a high-contrast medium in comparison to clean soils.

For instance, nuclear waste from weapons production is present in the groundwater and soil at certain sites across the country, posing potential threats to the environment. The contamination must not only be monitored but be better understood in order to clean it up.

PNNL researchers developed and are applying Real-time Four-Dimensional Subsurface Imaging Software![]() to determine the extent of contamination and what's driving its migration. No other commercial subsurface modeling software constructs 3D, time-lapse images of how the subsurface environment changes over time, in real time.

to determine the extent of contamination and what's driving its migration. No other commercial subsurface modeling software constructs 3D, time-lapse images of how the subsurface environment changes over time, in real time.

"Snapshots" of subsurface conditions are collected by measurements made at the surface or by electrodes inserted in boreholes that pass an electrical current through the material being studied and record how difficult it is for that electrical current to move through the material.

E4D-RT combines supercomputers to analyze large amounts of data with real-time imaging and the ability to model buried metallic infrastructure — like tanks and pipes. E4D-RT is a cost-saving open source solution for imaging in many kinds of subsurface studies — including fluid movement in geothermal systems and hydraulic fracturing operations and even understanding volcanic activity.

E4D-RT was developed by PNNL's Tim Johnson. DOE's Office of Science and Office of Environmental Management

and Office of Environmental Management supported the technology's development.

supported the technology's development.

Carbon Capture Simulation Initiative Toolkit – Nomination submitted by National Energy Technology Laboratory, team includes PNNL's Xin Sun

Power plant carbon emissions could be captured with the help of more detailed information and with reduced technical risk thanks to a computational technology called the Carbon Capture Simulation Initiative, or CCSI, Toolset. The suite of computational tools and models supports and accelerates the development, scale-up and commercialization of various post-combustion carbon-capture technologies, including solvent- and sorbent-based capture.

It does so by supporting a more thorough vetting of options, complete understanding of how processes will operate at scale under relevant field conditions, and increased understanding of how uncertainty affects risk. By improving learning and reducing risk as carbon-capture technologies are being scaled up, the CCSI Toolset can reduce the time needed to commercialize these technologies and provide greater confidence for those investing in carbon capture.

The technology was developed through the Carbon Capture Simulation Initiative , which was sponsored by the DOE's Office of Fossil Energy

, which was sponsored by the DOE's Office of Fossil Energy and led by DOE's National Energy Technology Laboratory

and led by DOE's National Energy Technology Laboratory . PNNL is one of five national laboratories involved in the initiative, along with industry and academic institutions. PNNL's Xin Sun led a team for the initiative that co-developed the CCSI Toolset. Others involved in the tool's development are current PNNL staff members Zhijie Xu, Kevin Lai, Varun Gupta, Chao Wang, Greg Whyatt, Feng Zheng and Charlie Freeman, as well as former PNNL staff members Emily Ryan, Avik Sarkar, Wei Xu and Wenxiao Pan. Photo courtesy of NETL.

. PNNL is one of five national laboratories involved in the initiative, along with industry and academic institutions. PNNL's Xin Sun led a team for the initiative that co-developed the CCSI Toolset. Others involved in the tool's development are current PNNL staff members Zhijie Xu, Kevin Lai, Varun Gupta, Chao Wang, Greg Whyatt, Feng Zheng and Charlie Freeman, as well as former PNNL staff members Emily Ryan, Avik Sarkar, Wei Xu and Wenxiao Pan. Photo courtesy of NETL.

2015

Columnar Hierarchical Auto-associative Memory Processing in Ontological Networks (CHAMPION) – Shawn Hampton, Rick Berg, Katya Pomiak, Patrick Paulson (PNNL); Ryan Hohimer, Alex Gibson and Peter Neorr (Champion Technology Company, Inc.); Frank Greitzer (former PNNL)

If you're a hacker aimed at stealing credit card information from a retail company and you want to evade detection, massive amounts of network data are your ally. Analysts have the know-how to sort through this digital mess, but they often identify attacks too late. Analytical software developed at PNNL can help find these and other threats in near-real-time. That's because the software, called Columnar Hierarchical Auto-associative Memory Processing in Ontological Networks or CHAMPION, has the knowledge to sort through data like an analyst, but on a much greater scale.

Scientists designed CHAMPION to use human analysts and historical data to learn about the company it's protecting. Starting with advanced Semantic Web technologies, which translate human knowledge into something that's machine readable, CHAMPION then uses descriptive logic to reason whether activity is suspicious. For example, if a retail company's HVAC data back-up account tries to access the point-of-sale system, CHAMPION could use historical data to conclude that this is unusual. Once identified, the software alerts an analyst of the suspicious activity — in time to potentially thwart an attack.

Cybersecurity isn't CHAMPION's only trick. Change its diet of knowledge and the software can learn to analyze financial services or health care data. PNNL licensed the software to Champion Technology Company Inc. to pursue all three applications.

Hydrothermal Processing (HTP) to Convert Wet Biomass into Biofuels – Doug Elliott, Dan Anderson, Rich Hallen, Todd Hart, Andy Schmidt (PNNL); James Oyler (Genifuel Corp.)

A new chemical processing system can convert natural substances as diverse as waste treatment sludge, food scraps and algae into a variety of useful fuels.

The system is remarkably efficient, in many cases converting 99 percent of a feedstock like algae into fuels, including biocrude oil, which can then be refined into aviation fuel, gasoline, and diesel fuel. The process also produces another fuel — methane gas — as well as clean water and useful plant nutrients such as nitrogen, phosphorous, and potassium.

Exotic though it sounds, the ability to make useful fuels out of biological materials like plants has long been possible. The difficulty has been doing so economically. The technology created by the PNNL team hurdles previous challenges by making it possible to skip a long, expensive, energy-intensive step that most processes require — drying out the raw material. Instead, the PNNL process works directly with the wet slurry of raw material, be it a waste stream from thousands of homes, scraps from a food-processing facility, or long strands of algae.

Alternate technologies typically recover much less energy from the raw material — often about one-third as much energy — and they typically cost much more. They also generally don't also produce other useful substances, such as clean water, burnable gas, and fertilizer.

Utah-based Genifuel Corp. has licensed the technology and built a pilot plant for its partner, Reliance Industries Ltd., to create biocrude oil from algae. The PNNL team is also working with the Water Environment Research Foundation to demonstrate the process's effectiveness with municipal wastewater.

Power Model Integrator: A System for More Accurate Energy Forecasts – Luke Gosink (PNNL); Ryan Hafen, Alex Venzin, Maria Vlachopoulou, Ning Zhou, Trenton Pulsipher (former PNNL)

Accurately forecasting future electricity needs is tricky, with sudden weather changes and other variables impacting projections minute by minute. Errors can have grave repercussions, from blackouts to higher energy costs.

The Power Model Integrator is a new forecasting tool that delivers up to a 50-percent increase in accuracy and the potential to save millions of dollars in wasted energy costs. Energy forecasters working for utilities and other power organizations currently rely on a combination of personal experience, historical data and their own preferred forecasting model. Each model tends to excel at capturing certain grid behaviors, but not necessarily the whole picture.

The Power Model Integrator simultaneously evaluates multiple models and determines how to best combine those models to make a single forecast that more accurately predicts future power needs. More accurate energy forecasts help reduce excess power generation, decrease the need to suddenly buy emergency power at a high cost and reduce the energy's carbon footprint.

Pressurized Magic Angle Spinning (PMAS) Technology for Nuclear Magnetic Resonance (NMR) Spectroscopy – David Hoyt, Jian Zhi Hu, Jesse Sears, Eric Walter, Hardeep Mehta, Kevin Rosso (PNNL); Flaviu Turcu (former PNNL)

A PNNL team created a way to make a sophisticated scientific tool much more useful for a variety of studies, including several aimed at answering important questions about energy and the environment.

The method boosts our ability to look at complex samples under conditions that more closely mimic their real-world environments. The technology brings together the power of nuclear magnetic resonance spectroscopy, which yields a remarkable peek into molecular interactions, and the ability to re-create the extreme conditions found on the tundra, in the deep ocean, or underground — conditions relevant to some of the biggest questions that scientists at DOE laboratories such as PNNL ask.

In the past, scientists have not been able to analyze solid materials, such as soil, minerals, biomass, biological materials or other structures, using NMR spectroscopy in its most effective mode, known as "magic angle spinning," while the samples were held under the high pressures or temperatures relevant to real-world reactions. The trouble is, once the samples are removed from those conditions, their physical properties or reactions can change significantly, limiting the usefulness of the data. The new technology allows scientists to tap NMR spectroscopy to watch molecular interactions as they occur in conditions that mimic their real surroundings.

The team has already applied the technology, called pressurized magic angle spinning, to several questions:

- Exploring the chemistry and other effects that occur when carbon is stored underground in a process known as carbon sequestration — an approach designed to reduce the amount of carbon in the atmosphere.

- Recreating the conditions found in fracking wells deep underground, where ultra-high pressures rule.

- Tracking the complex chemical reactions that occur when new biofuels made from plants are upgraded to useful fuels like gasoline or diesel fuel.

Subambient Pressure Ionization with Nanoelectrospray (SPIN) Source – Keqi Tang, Gordon Anderson Richard D. Smith, Ryan Kelly ( PNNL); Randall Pedder (Ardara Technologies); Jason Page, Ioan Marginean, and Jonathan Cox (former PNNL)

At the heart of mass spectrometry is the ability to precisely measure tiny samples of substances such as chemicals in soil and water or cancer cells in a tissue sample. Collecting the most molecules possible into the device is a key step: the more molecules, the more sure scientists can be that their findings are accurate.

The latest work builds on a previous PNNL creation of a device known as the Electrodynamic Ion Funnel. The ion funnel comprises a series of electrically charged rings that effectively funnel charged particles of interest into a small space where they can be measured and manipulated.

But collecting those particles and getting them into the ion funnel is challenging. Many of the ions simply escape before passing through the small aperture into the funnel. The new development, known as SPIN or Subambient Pressure Ionization with Nanoelectrospray, eliminates this problem by removing the aperture completely. The ion source now creates and sends particles to the funnel in a single system under the same atmospheric conditions, at just one-tenth the atmospheric pressure on top of Mt. Everest.

The net effect? Nearly 50 times as many gas-phase ions enter the mass spectrometer than without SPIN. That could mean greater sensitivity for assessing runoff of chemicals in soil, for example, or the ability to catch signs of cancer in the blood earlier than was previously possible.

2014

Glyph™ Wearable Media Device – Bruce Bernacki (PNNL); Allan Evans, Edward Tang, Neil Welch (Avegant Corporation)

Avegant's Glyph™ is the only wearable media device that solves the problem of how to view electronics screens comfortably and clearly for long periods of time. The technology was originally envisioned for military applications, such as night-time maneuvers and piloting armored or unmanned vehicles. But the headset has many more applications, including surgery and virtual training. Instead of a screen, the Glyph™ uses a micro-mirror array and a combination of proprietary optics in a head-mounted visor to reflect an image from an existing media source such as a television or gaming console. The image then is projected directly onto the back of the eye, effectively using the viewer's retina as a screen. The resulting image is extremely sharp and vivid, and looks as if the viewer is watching an 80-inch screen from 8 feet away. Because this approach mimics natural vision, the media-agnostic device avoids both eye strain and nausea, two typical aspects of near-eyed displays.

is the only wearable media device that solves the problem of how to view electronics screens comfortably and clearly for long periods of time. The technology was originally envisioned for military applications, such as night-time maneuvers and piloting armored or unmanned vehicles. But the headset has many more applications, including surgery and virtual training. Instead of a screen, the Glyph™ uses a micro-mirror array and a combination of proprietary optics in a head-mounted visor to reflect an image from an existing media source such as a television or gaming console. The image then is projected directly onto the back of the eye, effectively using the viewer's retina as a screen. The resulting image is extremely sharp and vivid, and looks as if the viewer is watching an 80-inch screen from 8 feet away. Because this approach mimics natural vision, the media-agnostic device avoids both eye strain and nausea, two typical aspects of near-eyed displays.

Bruce Bernacki and Allan Evans developed the initial technology for the Glyph™ at PNNL. Evans left PNNL to form Avegant where he commercialized the technology. Avegant licensed the technology from PNNL and began offering a commercial product in 2014. The technology went on to win a Federal Laboratory Consortium Award for Excellence in Technology Transfer in 2014 in addition to a number of industry honors.

SALVI: System for Analysis at the Liquid Vacuum Interface – Xiao-Ying Yu, Zihua Zhu, Bingwen Liu, Martin Iedema, Matthew Marshall (PNNL); James Cowin (former PNNL); Li Yang (Evans Analytical Group)

Many studies rely on precise knowledge of how solids and liquids interact on a molecular level, but liquids evaporate in the vacuum of certain instruments. PNNL developed the System for Analysis at the Liquid Vacuum Interface, or SALVI, that for the first time allows these instruments to image liquid samples in their natural state, at the molecular level in real-time and space.

SALVI can take a sample as small as two drops. The sample flows through a channel to a window the size of a pinhole, where an ion beam performs analysis. Surface tension keeps the liquid from escaping the window. The flow and small window reduce evaporation in a vacuum and protect the sample from beam damage, making many forms of liquid analysis possible.

SALVI enables imaging by more than one analytical instrument, and it eliminates the need for sample preparations such as freezing or drying biological cells. With SALVI, scientists can gain new insights about nanoparticles, bacteria, batteries and more. The team developed SALVI in collaboration with scientists at EMSL, the U.S. Department of Energy's Environmental Molecular Sciences Laboratory user facility at PNNL. SALVI was licensed to Structure Probe, Inc. in 2014.

STARS: Solar Thermochemical Advanced Reactor System – Robert Wegeng, Paul Humble, Robert Dagle, Daryl Brown, Dustin Caldwell, Richard Cameron, Feng (Richard) Zheng, Brad Fritz, Ward TeGrotenhuis (PNNL), Shankar Krishnan, Steven Leith, Dan Palo, Jair Lizarazo-Adarme (former PNNL); Richard Diver (DiverSolar LLC)

The Solar Thermochemical Advanced Reactor System (STARS) concentrates solar power to convert natural gas into synthesis gas (syngas). This syngas product enables natural gas power plants to make electricity while using 20% less fuel, thus reducing greenhouse gas emissions by 20% compared with conventional gas-fired plants. By incorporating meso-channel reactor technology, STARS sets a world record for converting solar energy to chemical energy, with 69% efficiency.

STARS represents a quantum leap forward from all other power generation choices available for new power plants today, because of its reduced carbon emissions, competitive cost, and ability to create syngas for electricity and transportation fuels. It also generates syngas that could be used to produce other chemicals, such as methanol and hydrogen. The research was largely sponsored by the U.S. Department of Energy's SunShot Initiative. SolarThermoChemical LLC licensed the technology in 2014.

2013

Combined Orthogonal Mobility & Mass Evaluation - Gordon Anderson, Erin Baker, Kevin Crowell, William Danielson III, Yehia Ibrahim, Brian LaMarche, Matthew Monroe, Ronald Moore, Randolph Norheim, Daniel Orton, Alexandre Shvartsburg, Gordon Slysz, Dick Smith, and Keqi Tang (PNNL). Contact: Erin Baker

The Combined Orthogonal Mobility & Mass Evaluation Technology (CoMet) platform addresses the triple challenge of specificity, sensitivity, and speed in analyses of complex biological and environmental samples by providing more comprehensive coverage of smaller samples with higher measurement throughput. CoMet synergistically integrates the ion mobility and mass spectrometry approaches, enabling rapid ultrasensitive analyses of extremely complex materials and allowing separation, identification, and characterization of species indistinguishable by mass spectrometry alone.

With unsurpassed analytical capabilities that include swift detection, attribution, and quantification of rare yet extraordinarily important components in enormously complex organic mixtures, such as proteomes or metabolomes in human or animal tissues, or natural samples such as petroleum or soils, CoMet will open major new avenues in biomedical research, clinical practice, and natural product management. Suitable for either global or targeted analyses, this platform will be a cost-effective universal tool for a broad range of applications in science and industry.

2012

Graphene Nanostructures for Lithium Batteries - Wendy Bennett, Daiwon Choi, Gordon Graff, Jianzhi Hu, John Lemmon, Xiaolin Li, Jun Liu, Donghai Mei, Vijayakumar Murugesan, Zimin Nie, Kevin Rosso, Laxmikant Saraf, Birgit Schwenzer, Yongsoon Shin, Maria Sushko Chongmin Wang, Wei Wang, Jie Xiao, Wu Xu, and Jason Zhang, (PNNL); John Lettow (Vorbeck Materials); and Ihan Aksay (Princeton University). Contact: Jun Liu

Researchers at PNNL, partnering with Vorbeck Materials and Princeton University, innovated methods for applying graphene to lithium batteries to improve on current lithium ion (Li-ion) battery technology and to forge a path for next generation lithium-sulfur (Li-sulfur) batteries, and possibly down the road, lithium-air (Li-air) batteries. Using Vorbec's proprietary functionalized graphene sheet material, these new graphene-based battery electrodes offer significant advantages to lithium battery technologies. The unique properties of graphene, combined with specifically designed chemical modification of the graphene and assembly into novel structures, have advanced the limit on what is feasible for lithium battery energy storage. The new material delivers increased battery capacity, longer cycle life, and twice as much power at high charge and discharge rates, the latter of which are critical to expanding the adoption and use of electric vehicles. Using a battery with graphene-based electrodes, a cell phone could be fully recharged in less than ten minutes versus the typical two to five hours.

The technology is licensed to Vorbeck, who is co-recipient of the award with PNNL and Princeton University.

Advanced Carbon-dioxide Removal Unit - Tim Bays, Ken Buxton, Dustin Caldwell, April Carman, Glen Fryxell, Dennis Mullen, Ken Rappe, Jake Tucker, Jesse Willett, and Tom Zemanian (PNNL); Ken Eischeid (Steward Advanced Materials). Contact: April Carman

The supply and replenishment of oxygen aboard the U.S. Navy's fleet of submarines must be taken carefully into account and adapted to the unique environment, which is why shipboard air purification systems are critical. One of the major challenges for a system in this environment is effective removal and disposal of carbon dioxide, or CO2. Existing removal techniques involve legacy systems with serious and long-standing issues the Navy has been highly motivated to solve. This led to a partnership with PNNL, and a technology transfer that yielded the partners an Interagency Partnership Award—a first for PNNL—from the Federal Laboratory Consortium. The Advanced Carbon-dioxide Removal Unit technology—or ACRU—is a versatile air purification system that employs a novel granular sorbent material, developed at PNNL, to effectively target and efficiently and effectively remove CO2 from breathing air in confined spaces, such as on submarines. It also meets the need for regeneration capability—extending the useful life of the sorbent—thus promoting effective operation of the purification system for long stretches of time. And its byproducts are nonhazardous. Manufacturing rights for the new ACRU sorbent material—a new version of PNNL's award-winning SAMMS® technology—are licensed to Steward Advanced Materials. The first ACRU that will house the sorbent when installed in its first U.S. Navy submarine is being manufactured by The Hamilton Sundstrand Corporation.

2011

Array Detection Technology for Mass Spectrometry - David Koppenaal, Charles Barinaga (PNNL); Bonner Denton, Roger Sperline (University of Arizona); Gary Hieftje, James Barnes, Greg Schilling, Steve Ray, Jeremy Felton (Indiana University); Eugene Atlas (iMAGERLABS); Dirk Ardelt (SPECTRO Analytical Instruments/Ametek). Contact: Dave Koppenaal.

The Array Detection Technology for Mass Spectrometry represents a breakthrough in mass spectrometry detectors, employing thousands of micro-fabricated detectors arranged in a dense array and electronically integrated into a single monolithic chip-based device to simultaneously monitor and detect wide mass ranges. This allows the entire composition of a test sample to be analyzed in a single run, which saves time, increases efficiency, and considerably simplified the analysis process. Conventional detectors have historically only been able to detect a single mass or a small range of masses at one time, meaning all other chemical information for a given analysis was lost or undetected, and multiple scans or runs were required to detect and analyze an entire chemical sample. This new technology—developed in collaboration with the University of Arizona, Indiana University, and California-based iMAGERLABS—is highly desirable for a number of analytical applications, some of which include nonproliferation monitoring, forensics, environmental monitoring, and industrial hygiene. It is licensed to SPECTRO/Ametek, who launched the first commercial implementation of the detector in a mass spectrometry instrument product in 2010.

Dynaforge—A Solid-State Dynamic Powder Compaction Process for Production of High-Performance Tools and Dies - Darrell Herling, Yuri Hovanski, Siva Pilli (PNNL); Louis Lherbier, David Novotnak (Carpenter Powder Products). Contact: Darrell Herling.

From windshields to paperclips to house keys, to toy cars, to the nuts and bolts that hold furniture together—there are thousands of items that we use in our everyday lives that are mass produced using specialized tooling and die sets. Such processes require exceptionally high temperatures to produce the items, requiring tools that can withstand the tremendous stress put on them during production; a need the industry hasn't had a solid answer for until now. Dynaforge is a new commercial process for manufacturing tools and dies that are more resistant to extremely high temperatures and stresses. Developed by Pennsylvania-based Carpenter Powder Products, and extensively tested, analyzed, and refined with the help of researchers at PNNL, the Dynaforge process improves tooling and die life by an average of five times, lowering the frequency and relative direct and indirect costs of downtime to replace broken tooling, and thus the long-term cost per part. Its principal market is in automobile manufacturing for primary hot forming processes such as die casting of metal parts for the power train, and forging for suspension and steering components.

2010

GammaTracker™ - Carolyn Seifert, Mitch Myjak, Scott J. Morris, Les Kirihara, Michael Batdorf, Brion Burghard, Luke Erikson, Ryan Slaugh, Duane Balvage, John Rohrer, Michael Hughes (PNNL); Zhong He, Feng Zhang (University of Michigan); Douglas Lee (Kansas City Plant). Contact: Cari Seifert.

The GammaTracker is an automated, rugged, low-power handheld radioisotope detection unit with sensitivity on par with existing competing alternatives, but with better resolution and increased source identification reliability in a much smaller, self-contained package. And, for the first time ever in handheld radioisotope detection, the GammaTracker can point users to the direction of gamma-ray sources in real time using a generated visual distribution map.

The technology is the result of a key collaboration between PNNL, the Kansas City Plant, and the University of Michigan.

IncubATR™ - the Live-Cell Monitor - SK Sundaram, Brian Riley, Thomas Weber, Colette Sacksteder, R. Shane Addleman (PNNL); John Peterman (Simplex Scientific). Contact: S.K. Sundaram.

The ability to test live cells is critical to observing true cell behavior in many applications in the areas of biomaterials, nanomaterials, product evaluation for potential health hazards, drug testing, and screening for medical and pharmaceutical biomarkers. The ability to do so reliably will accelerate material, biological, and medical discovery and innovation; reduce laboratory and industry costs; and, limit the need for live-animal testing in some applications. Designed specifically for Fourier transform infrared (FTIR) spectroscopy, scientists at PNNL invented the IncubATR-the Live-Cell Monitor (IncubATR) to provide a cost-effective rapid-screening option for achieving these goals. The technology is licensed to Middleton, Wisconsin-based Simplex Scientific, who is currently developing a commercial version of the product.

Ion Mobility Spectrometer on a Microchip - Alexandre Shvartsburg, Keqi Tang, Dick Smith (PNNL); Paul (Billy) Boyle, Andrew Koehl, David Ruiz-Alonso, Danielle Toutoungi (Owlstone Ltd). Contact: Alex Shvartsburg.

The Ion Mobility Spectrometer on a Microchip is a new, miniaturized device that accelerates the speed of analyses using ion mobility separations by over 100 times, enabling capabilities for rapid and confident monitoring of a broad range of chemicals at very low concentrations. Capitalizing on the leading-edge nanofabrication techniques of partner Owlstone Nanotech and the latest developments in Field Asymmetric waveform Ion Mobility Spectrometry (FAIMS) at PNNL, the dime-sized device employs a scalable multichannel architecture for high-speed separations of ions in the gas phase. It can easily be integrated with an air sampler, ionization source, and detector to yield a powerful gas analyzer and a chemical monitor in a portable, self-contained unit. Current primary applications for this technology include explosive and chemical warfare agent detection and, when integrated with mass spectrometry, complex proteomic and metabolomic sample analysis.

Propylene Glycol from Renewable Sources - Alan Zacher, John Frye (PNNL); Todd Werpy (Archer Daniels Midland Company); James F. White (3RiversCatalysis LLC). Contact: Alan Zacher.

Propylene glycol, used to make the chemicals needed to produce everyday industrial and consumer products, has historically only been produced from petroleum–about 2-to-2.5 billion pounds of it per year to meet U.S. demand alone–to the detriment of the natural environment. The Propylene Glycol from Renewable Sources (PGRS) process offers an environmentally friendly, cost-competitive and commercially viable alternative by converting plant-based, seed-oil-derived glycerol, sugars, or sugar alcohols to propylene glycol. The PGRS process is licensed to Archer Daniels Midland Company, which has recently completed construction on a full-scale production facility for the purpose of mass-manufacturing and commercializing the renewable chemical product.

Micro Power Source - Mark Gross, Gordon Graff, Jiguang (Jason) Zhang, Wendy Bennett, Charles Bonham (PNNL); David Stein, Carlos Sanchez, Darlene Udoni, Rob Jarecki, Randy Shul, Doug Greth, Christine Ford, Todd Bauer (Sandia National Laboratories); Simon Nieh (Front Edge Technology, Inc); Jenn-Ming Yang, Yuhuan Xu (UCLA Henry Samuel School of Engineering and Applied Science). Contact: Mark Gross.

A joint effort with Sandia National Laboratories, Front Edge Technology Inc, and the UCLA Henry Samuel School of Engineering and Applied Science, Micro Power Source combines five innovations, including an ultra-thin sealing material developed at PNNL, into an ultra-small form factor, self-charging power source encapsulated in a polymer coating. It functions by integrating a lithium-ion based solid-state battery with a thin photovoltaic collector, resulting in an environmentally friendly power source with likely applications including self-power smart cards, environmental sensors, and tags for material tracking. The new technology has been licensed to Front Edge.

2009

Perpetua Power Puck™ - John DeSteese, Larry Olsen (PNNL); Paul McClelland, Jon Hofmeister (Perpetua Power Source Technologies).

Electricity can be created by processing heat associated with naturally occurring temperature differences in the environment. This essentially inexhaustible source of heat can be converted into electrical power sufficient to run compact, low-power devices like wireless sensors for decades. The Perpetua Power Puck™ harvests energy from its surrounding environment with the capability for replacing outright conventional chemical batteries.

The Power Puck is a renewable energy source that has no moving parts, which makes it more efficient and cost-effective than other technologies. The technology can save time and money in situations where information needs to be collected and power sources need to be maintained at remote sites, such as dams, bridges and pipelines. These energy harvesters are expected to last as long as the sensors and transmitters they power.

The Perpetua Power Puck is being marketed for industrial automation, military, energy efficient buildings and other applications. It is based on technology developed at PNNL called the Thermoelectric Ambient Energy Harvester [PNNL news release] and licensed to Perpetua Power Source Technologies , based in Corvallis, Ore. PNNL received the R&D 100 award in partnership with Perpetua.

, based in Corvallis, Ore. PNNL received the R&D 100 award in partnership with Perpetua.

Ultrasensitive Electrospray Ionization Mass Spectrometry Source & Interface - Richard Smith, Ryan Kelly, Jason Page, and Keqi Tang.

Scientists at PNNL have achieved a 40-fold increase in the sensitivity of mass spectrometry instrumentation that will benefit applications in human health, the environment, and pharmaceutical and petrochemical industries. The Ultrasensitive ESI-MS Source & Interface integrates four technologies to provide greater sensitivity and precise measurements while requiring smaller samples.

Mass spectrometry instrumentation enables the analysis and identification of broad types of samples and ranges of chemical compounds. It's commonly used for environmental and health analyses, as well as by industry for pharmaceutical and petrochemical product development. The most broadly useful methods for chemical and biochemical samples use electrospray ionization-mass spectrometry (ESI-MS).

PNNL's improved ESI-MS instrumentation can measure amounts of compounds in a sample very precisely, even when very little material is available - which is especially important when sample sizes are limited, such as from microbiopsies of human tissue.

PNNL scientists are using the improved sensitivity in studies to develop biomarkers for early disease diagnosis, drug target discovery and basic biological research. The laboratory is also engaged in a collaboration with a major vendor of mass spectrometry instruments to further explore the benefits of the new ESI-MS system.

2008

Grid Friendly™ Appliance Controller - Robert Pratt, David Chassin, Jeffery Dagle, Donald Hammerstrom, Larry Reid, Michael Kintner-Meyer, Paul Boyd. Contact: Robert Pratt.

The GFA Controller is a small circuit board built into household appliances that reduces stress on the power grid by continually monitoring fluctuations in available power. During times of high demand, appliances equipped with the controller automatically shut down for a short period of time, resulting in a cumulative reduction that can maintain stability on the grid. The GFA Controller received a Federal Laboratory Consortium award for Excellence in Technology Transfer in 2007.

Multi-Scale Materials Integrated Processing Method - S.K. Sundaram, Mike Schweiger, Brad Johnson, Brian Riley (PNNL); Brett MacIsaac (Battelle); Juliana Olmstead (former grad student). Contact: S.K. Sundaram.

This technology is the only integrated, single-step process materials fabrication method that generates nano- to macro-sized materials with identical chemistry characteristics for use in materials science research and development applications. The ability to create these materials from one process reduces the risk of impurities in these materials and improves consistency. The result is higher-quality products that can be used for advanced materials, components, devices, and their integration by materials scientists, engineers, designers and users for broad range of applications.

Battelle-RDF: Environmentally Benign and Reduced Corrosion Runway Deicing Fluid - Satya Chauhan, Nick Conkle, Melissa Roshon (Battelle); Bill Samuels (PNNL). Contact: Satya Chauhan or Bill Samuels.

The D3 is a family of non-toxic biodegradable fluids used to remove and prevent the formation of snow and ice on aircraft, airport runways, roads, and pavement. It can also prevent snow from sticking to deiced surfaces, providing additional protection.

Removing ice and snow from these types of surfaces is a high priority to ensure transportation safety worldwide, but the high toxicity levels of previous deicing products posed environmental threats. D3 was developed to be more environmentally friendly and is manufactured primarily from bio-based materials. The material substantially reduces toxicity levels and potential environmental damage while providing the same performance and benefits of other commercial deicing products.

Velocys-FT: Fischer Tropsch Fuels Using Velocys Microchannel Technology - Jeff McDaniel, Terry Manzanec, Anna Lee Tonkovich, Laura Silva, Frank Daly, Kai Jarosch, Tim Sullivan, Sean Fitzgerald, Maddalena Fanelli, Rachid Tacha, Bob Litt, Wayne Simmons, Jenn Marco, Mike Lamont, Jeff Marco, Eric Daymo, Harley Freeman, Luke Schrader, Ravi Arora, Dongming Qiu, Paul Neagle, Mike Marchiando, Tom Yuschak, Steve Perry, Bin Yang, Soumitra Deshmukh, Bob Luzenski, Dave Kilanowski, Jan Lerou (Velocys, Inc.); Yong Wang, Dean Matson (PNNL); Satya Chauhan, Brad Chadwell, Christopher Brandon (Battelle). Contact: Jeff McDaniel.

Velocys-FT is an advanced reactor technology that greatly reduces the size and cost of second-generation biofuel facilities. First-generation biofuels, including corn ethanol and biodiesel, are prevalent today but are an interim solution because they use food crops for raw material. Next-generation biofuels, ones that use non-food biomass, are a more sustainable choice. Velocys-FT can help next-generation biofuels be produced more inexpensively at smaller-scale facilities. Primary benefits include favorable economics at smaller scales, more easily deployed and modular units and improved heat transfer. Velocys led its development with contributions from Battelle and PNNL.

2007

Functionalized Nanoporous Thin Films (FNTF) - R. Shane Addleman, Glen Fryxell, Richard Skaggs, Xiaohong Shari Li. Contact: Shane Addleman or Rick Skaggs.

FNTF is used to coat sampling discs that can then be used to easily capture and concentrate heavy metal contaminants in water sources. The FNTF sampling discs can then be quickly analyzed with X-ray fluorescence spectroscopy to detect the presence of toxic metals. The FNTF technology significantly expands and enhances sampling and testing capabilities, resulting in the ability to test water for virtually every heavy metal with potential to negatively affect human health and the environment. The technology also increases sensitivity by more than a thousand times the previous capability. The technology was developed with PANalytical, an international supplier of analytical instrumentation and software for X-ray diffraction and X-ray fluorescence spectrometry.

PNNL's FNTF technology was also recognized in the September 2007 issue of R&D Magazine as one of the top 25 micro- and nanotechnologies of the year.

Microchannel Gas-Liquid Processing Device - Ward TeGrotenhuis, V. Susie Stenkamp, Feng (Richard) Zheng. Contact: Ward TeGrotenhuis.

This technology manages heat and recovers water to balance consumption in fuel cell systems and fuel processors. Its compact size and ability to operate in a wide range of conditions make it ideal for use in portable or mobile fuel cell applications including vehicles, auxiliary power supplies, and electronics systems. The device is also useful for distilling diesel fuel to aid in removing sulfur so that it can be converted to hydrogen. It was developed with funding from NASA and DOE's Energy Efficiency and Renewable Energy office.

Universal Parsing Agent (UPA) - Alex Gibson, Mark Whiting, James Brown, Wendy Cowley, Nick Cramer, Patricia Medvick, Dennis McQuerry, Anne Schur, Ryan Scott, Marie Whyatt. Contact: Alex Gibson.

The UPA is a document analysis and transformation software program that accepts multiple information streams or datasets, finds and extracts the information needed, and delivers results in the format that will be most useful. It is flexible and adaptable to individual user needs, and can be used to identify and extract very specific or very broad ranges of information. UPA was developed for a variety of U.S. government clients. Most recently a version was deployed at the Environmental Protection Agency to support a large web content management system. UPA may be used anywhere people fight battles with information overload. Applications currently range from supporting our government's Global War on Terror to commercial business intelligence efforts.

2006

The Cesium-131 Brachytherapy Seed - Larry Greenwood, Mark Murphy, Darrell Fisher, Deborah Coffey, Chuck Soderquist, Roman Piper (PNNL), David Swanberg, Donald Segna, Lane Bray, Garrett Brown, Matthew Bales, Clay O’Laughlin, (IsoRay Medical), Christopher Smith (Intellegration); James Madsen (Columbia Basin Consulting Group), Leroy Korb (Cancer Care Center, Warren, PA). Contact: Larry Greenwood or David Swanberg.

This powerful new prostate cancer treatment developed jointly by IsoRay and Pacific Northwest National Laboratory has been acclaimed by doctors as the most significant advance in seed implant therapy in more than 15 years. The ground-breaking IsoRay cesium-131 brachytherapy seed has been FDA-cleared to deliver a precisely measured radiation dose to malignant tumors of the prostate as well as other major organs. The seed’s innovative design delivers its therapeutic radiation faster and more evenly than other radioisotopes and its short half-life minimizes and provides faster resolution of side effects associated with radiation therapy.

e-RESS: revolutionary nanoparticulate coating process - John Fulton, George Deverman, Clement Yonker, (PNNL), James McClain, Charles Douglas Taylor, James DeYoung (Micell Technologies). Contact: John Fulton.

The e-RESS (Electro-State Rapid Expansion of Supercritical fluids) process is a new method to deposit nanoparticulate coatings in a few simple processing steps, and is expected to give cardio-implant patients the comfort of better drug delivery and longer implant integrity. The e-RESS technology provides a method for inhibiting the rate of tissue re-growth over medical implants, such as vascular stents, which should result in longer-lived stents and reduce the need for replacement surgeries. The e-RESS process also provides a method for combining coating elements to improve control over time-release properties of therapeutic agents.

Surface-Induced Mineralization Technique for Calcium-Phosphate Coatings Incorporating Therepeutic Agents (SIM) - Allison Campbell, Peter Rieke, Xiahong Shari Li, Barbara Tarasevich, (PNNL), Lin Song, Marisol Avila. Contact: Allison Campbell.

SIM is a novel water-based technique that allows a biocompatible calcium-phosphate coating enhanced with a therapeutic agent to be deposited on orthopedic implants and other medical devices, such as catheters and stents. The coatings can reduce or eliminate bacteria growth that causes post-surgical infection. The water-based deposition process combined with therapeutic agents also allows for enhanced bone bonding of artificial joints by providing an advanced method for applying pure calcium-phosphate coatings, which are a natural component of bone.

Ti MIM: a new technique for Titanium Metal Injection Molding - Eric Nyberg, Kevin Simmons, K. Scott Weil, (PNNL). Contact: Eric Nyberg.

Pacific Northwest National Laboratory has developed a process that speeds up production time and could dramatically reduce costs for forming high-quality titanium parts, without generating toxic waste that requires disposal. The Ti MIM process incorporates a proprietary binder for injection molding of titanium that reduces or eliminate impurities in the metal, as well as reducing the time and cost of producing strong, lightweight, corrosion-resistant titanium parts for use in the biomedical, automotive and aerospace industries.

MilliWave Thermal Analyzer - SK Sundaram, (PNNL), Paul Woskov, (Massachusetts Institute of Technology) William Daniel, Jr., (Savannah River National Laboratory). Contact: SK Sundaram.

The MilliWave Thermal Analyzer, developed jointly by the Massachusetts Institute of Technology, Savannah River National Laboratory and Pacific Northwest National Laboratory, is a thermal analysis instrument that uses millimeter-wave electromagnetic radiation to measure the temperature, amount of energy emitted, and physical change of materials, processes, and systems. This technology can function under extreme environments (such as very high temperatures) because contact is not required between the instrumentation and the materials; therefore, sampling of the materials is not required and the measurements can be made in real-time.

2005

The Morning Report: Advanced Proactive Safety and System Monitoring Tool - Thomas A. Ferryman (PNNL), Brett G. Amidan (PNNL), Irving C. Statler (NASA Ames), Thomas R. Chidester (NASA Ames), Loren J. Rosenthal (BMI), Robert E. Lynch (Flight Safety Consultants), Gary L. Prothero (ProWorks Corp) and Robert E. Lawrence (Safe Flight). Contact: Tom Ferryman.

*R&D Magazine's 2005 Editors' Choice Award for "Product with the Greatest Impact on Safety"

The Morning Report is a computational tool used to analyze large datasets of aviation information collected by onboard aircraft instruments. The software and algorithms can be extended to other domain applications to monitor massive amounts of data and identify typical patterns and atypical events thus enabling domain experts to monitor complex systems.

Continuous analysis of flight data can be used by aviation safety experts and airline policy makers to determine subtle but potentially serious safety issues. Every day The Morning Report analyzes gigabytes of the day's flight information and presents data the next morning in tabular or graphical reports. The reports allow aviation safety experts to rapidly pinpoint anomalies, share information with other decision makers and possibly prevent accidents. While the technology utilizes complex mathematical and statistical algorithms it is easy to operate via a simple desk-top application.

This is the first technology developed that can use a new paradigm in data-intensive computing to distill “insight” from massive amounts of data covering numerous nuances, including un-envisioned nuances, of thousands of flights to make aviation safer. Before The Morning Report, there was no way for all of these data to be boiled down into a form that would be useful to aviation safety experts or airline policy makers. The mathematics of The Morning Report reveal events and conditions that could be prerequisite to situations that flight safety experts had not perceived as problematic or even knew were occurring during routine flights. Once recognized, the airlines have the insight to rectify these practices before they become a safety problem—and before lives are lost.

The Morning Report award is shared with co-developers: NASA Ames Research Center, Battelle, Flight Safety Consultants, ProWorks Corporation and Safe Flight.

More information about this technology, including a 5-minute movie, can be found at PNNL's Statistical Sciences website.

2004

BSP3 Polymer - Jay W. Grate (PNNL), Steven N. Kaganove (Michigan Molecular Institute), David A. Nelson (PNNL) Contact: Jay Grate

A novel carbosiloxane polymer has been developed at Pacific Northwest National Laboratory (PNNL) that can be used in chemical detector systems to detect airborne chemical agents such as nerve agents that might be used in a terrorist attack. The patented polymer (“BSP3”) has been licensed to BAE Systems, which is developing the ChemSentryTM 150C chemical vapor detector system. The polymer coats the surface of a sensor chip in the chemical detector and absorbs vapor molecules from the air so the sensor can detect them. Chemical detectors can be used as counter terrorism devices to monitor the safety of air in buildings and subways and to protect first responders at terrorist incidents or chemical accidents. Compared it to its predecessor polymer, fluoropolyol, BSP3 made sensors four times more sensitive to nerve agents. In surface acoustic wave (SAW) sensor array systems using a preconcentrator, the BSP3 polymer enabled faster detection to lower concentrations than was previously possible.

Polymers applied to the surfaces of SAW sensors determine their sensitivity and selectivity by collecting and concentrating vapor molecules from the gas phase onto the sensor surface by reversible sorption. The BSP3 polymer has been designed and synthesized especially for sensors in array-based chemical detectors. Each sensor in a sensor array system has a different coating, so the collective responses of the array provide a characteristic pattern, or “fingerprint” to a given analyte vapor. When chemical vapors are detected, the pattern of responses from the array is used to recognize and distinguish one chemical compound from another. Compared to other sensing polymers, BSP3 has an exceptionally strong capability to absorb toxic organophosphorus compounds such as nerve agents, leading to high sensitivity and distinctive array patterns. BSP3 is superior for use in nerve agent sensing because it has both the necessary chemical interaction properties and the desired physical properties to provide rapid and sensitive chemical sensor responses. When used in arrays designed for other applications such as environmental monitoring, industrial hygiene, and process control, BSP3 increases the chemical diversity of coatings and thereby improves the sensor’s capability to distinguish one compound from another.

D3: Degradable by Design Deicer™ (Joint entry with Battelle Memorial Institute)—Satya Chauhan (Battelle Memorial Institute), H. Nick Conkle (Battelle Memorial Institute), William Samuels (PNNL), Sara Fauss Kuczek (Battelle Memorial Institute), Marisol Avila (PNNL), John Frye (PNNL), Kevin Simmons (PNNL)

Contact: Satya Chauhan

The D3: Degradable by Design Deicer™ is composed of a family of non-toxic, biodegradable fluids used to remove and prevent the formation of ice on military and commercial aircrafts, military and commercial runways, and roadways or pavement. The D3 is made from biobased materials and has less environmental impact on receiving waters, is much less corrosive and is less toxic than existing fluid and solid deicers.

Intellifit System—Douglas L. McMakin, Dale Collins, James M. Prince, Thomas E. Hall, David M. Sheen, Wayne M. Lechelt, Paul E. Keller, Ronald H. Severtsen (all PNNL)

Contact: Doug McMakin

*R&D Magazine's Editors' Choice Award for "Most Promising New Technology of 2004"

The Intellifit System is a first-of-its kind cylindrical holographic imaging technology that can perform a 360-degree whole body scan in less than 10 seconds. The Intellifit scanner uses a millimeter wave array/transceiver technology which bounces off the body reflecting more than 200,000 points in space. The array/transceiver illuminates the human body standing within the cylinder with extremely low-powered millimeter waves—a class of non-ionizing radiation not harmful to humans—that penetrates clothing and reflects off the body. The reflected signals are collected by the array/transceiver and sent to a high-speed image processing computer where the Intellifit software converts that “point-cloud” into dozens of precise body measurements forming a high-resolution 3D image of the body.

The Intellifit System, a commercialization of PNNL’s millimeter wave holographic scanner, provides significant, credible technology that will inexpensively solve a large part of the product markdown/return problem for apparel retailers and manufacturers, and the consumers who are buying and returning their clothing. The Intellifit System adds value to every participant in the clothing buying cycle—from the designer, to the manufacturer, to the retailer, to the customer. Intellifit allows designers to understand who their customers are and how, in the real world, they are sized, shaped, and proportioned. Intellifit Specifications and Patterns help manufacturers, anywhere in the world, create garments that fit real people in their targeted demographic.

Parallel commercialization of another embodiment of this technology is taking place on the security front. This application of the technology is called D3P, Dual Panel Planar Portal, and could minimize the extra delays of searches with hand-held metal detectors and the indignity of physical searches to resolve ambiguous alarms. The D3P can harmlessly and quickly scan a person and generate an image with such clarity that all the items inside the clothing and shoes of that person are recognizable, regardless of the materials from which they are made.

Single-Chain Antibody Library—Michael J. Feldhaus (PNNL), K. Dane Wittrup (Massachusetts Institute of Technology), Lee K. Opresko (PNNL), Robert W. Siegel (PNNL), H. Steven Wiley (PNNL)

Developed by the Pacific Northwest National Laboratory (PNNL) and the Massachusetts Institute of Technology (MIT), the Single-Chain Antibody Library provides researchers with an easy-to-grow library of more than one billion artificial antibodies. These antibodies—produced by genetically engineered brewer’s yeast—offer an inexpensive method for creating and producing antibodies for research. Antibodies play an increasingly important role in the biomedical and pharmaceutical industries as effective tools for recognizing specific molecules. For example, in medical treatments, antibodies are injected into the body to seek out specific proteins on cancerous cells, and target treatment to those cells. Biowarfare sensors can also use antibodies to detect proteins associated with harmful agents. Antibodies also are expected to play a major role in helping scientists to more fully understand various biological processes by identifying which proteins are present in a given functional state and if they interact with other specific proteins in the cell.

Nanomolar-affinity scFvs (single chain Fragment variables) are routinely obtained by magnetic bead screening and flow cytometric sorting. This yields clones of yeast cells that contain the gene encoding the scFv. The biochemical and biophysical properties of the scFv clones can be evaluated directly on the yeast cell surface by immunofluorescent labeling and flow cytometry, eliminating the separate subcloning, expression, and purification steps typically necessary to find and extract unique antibodies. Using multiple antigens to screen the library simultaneously saves the researcher an enormous amount of time – days as compared to weeks or months with other current technologies. The ability to use multiplex library screening allows this approach to be used for high-throughput antibody isolation necessary for proteomics applications.

PNNL’s Single-Chain Antibody Library could replace the need to produce antibodies using animals and presents new possibilities for rapidly designing medical treatments more compatible with the human immune system. It provides greater benefit over similar but older technologies by: using a novel identification process that allows researchers to screen and identify needed antibodies, in days rather than months; saving research dollars by reducing time and labor cost; enabling the rapid reproduction of selected antibodies; and controlling the expression of antibodies to allow library expansion while maintaining diversity.

2003

FT-MS Proteome Express—Richard D. Smith, Harold R. Udseth, Gordon A. Anderson (PNNL), Mark A. Wingerd, and Mikhail E. Belov (former PNNL staff). Contact: Richard D. Smith

This breakthrough technology not only significantly accelerates proteome analysis but also provides accuracy and depth never previously reached in proteomic studies. It is the first-ever high-throughput Fourier-transform ion cyclotron resonance mass spectrometer (FT-MS) with an unprecedented ability to characterize and identify proteins, especially those that exist in small quantities. It provides quantitative analyses of “proteomes,” the collection of proteins that make up a cell or organism under a specific set of conditions at a specific time.

This capability enables application of the FT-MS Proteome Express to understanding the role proteins play in diseases, such as cancer, and provides a basis for developing treatment drugs. The FT-MS Proteome Express will revolutionize the scientific community’s ability to understand biological systems and to develop biotechnological solutions for the nation’s most pressing energy and environmental problems.

Product Acoustic Signature System (PASS)—Aaron Diaz, William C. Cliff, Richard A. Pappas, Brion J. Burghard, James R. Skorpik, Larry D. Reid, Juan D. Valencia, Brian J. Tucker, Kayte M. Judd, Joe C. Harris, Todd J. Samuel, O. Dennis Mullen. Contact: Aaron Diaz

PASS is an acoustic inspection device that uses ultrasonic pulse echo technology to non-intrusively interrogate and identify the contents of sealed containers. With PASS in hand, Customs inspectors can tell if the tanker truck or barrel in front of them contains crude oil, vegetable oil, or chemical weapons agents. PASS can also detect hidden packages and compartments and determine the container’s fill level - all without having to open lids and conduct time-consuming, potentially hazardous physical sampling and searches.

PASS was developed at Pacific Northwest National Laboratory and is licensed to Mehl, Griffin, & Bartek, Ltd. which is manufacturing and marketing the device. It gives Customs officials a valuable tool in their efforts to identify weapons of mass destruction, stop smuggling, enforce tariffs, and deter illicit drug trafficking. PASS also provides one of the safest, simplest means available for inspecting chemical weapons and for uncovering weapons smugglers at international borders. While it helps keep commerce moving, PASS provides that ounce of prevention critical to homeland security and can play an integral role in the verification activities needed to help maintain world stability.

The Starlight Information Visualization System—John S. Risch, John D. Pinto, Scott T. Dowson, Michelle L. Hart, Wes L. Hatley, Brian D. Moon, Bruce Rex (PNNL); Edward R. (Randy) Woodson III (Battelle Alexandria Operations (BCO)), Edwin C. “Chuck” Knutson (Object Sciences Corp.), Richard Leenstra, Lance Otis, and Tom Bougan (Applied Technical Systems, Inc.), Anne Kao, Steve Poteet, Jason Wu, William Ferng, Ole Larsen, Shan Luh, Dan Pierce, and Andrew Booker (Boeing Phantom Works). Contact: John S. Risch

Starlight launches a new generation in visualization technology by uncovering key relationships hidden in large, complex, dynamic information collections. Unlike other technologies, Starlight integrates structured, unstructured, spatial, and multimedia data, offering comparisons of information at multiple levels of abstraction – simultaneously and in near real-time.

Starlight is unlike any other information analysis tool. It is designed to capture and graphically depict complex relationships in data from multiple information sources. By making such relationships simultaneously visible Starlight enables exciting, rapid, and powerful new forms of concurrent information exploitation. The result is an unprecedented approach to information management and sense-making.

2002