Technology Overview

Bioenergy researchers have long worked to develop self-sustaining processes for converting sewage, agricultural waste, and more into fuels, while keeping carbon waste out of the atmosphere and water.

Typically, when waste is converted into biofuels, a byproduct is wastewater that includes carbon- and harmful oxygen-containing compounds. One example of an effective method for converting waste to fuels is hydrothermal liquefaction (HTL). HTL converts wet biomass into an energy-dense biocrude oil and produces an aqueous phase. While the conversion takes hours instead of nature’s millions of years, the wastewater produced requires further treatment to remove potentially harmful compounds.

The Clean Sustainable Electrochemical Treatment—or CleanSET— developed by researchers at Pacific Northwest National Laboratory (PNNL) cleans wastewater by turning previously unrecoverable waste carbon into valuable chemicals, while simultaneously generating useful hydrogen to power vehicles or generate heat.

The electrochemical system operates under mild conditions and can be powered by the renewable source of electricity, making it inexpensive to operate and potentially carbon neutral.

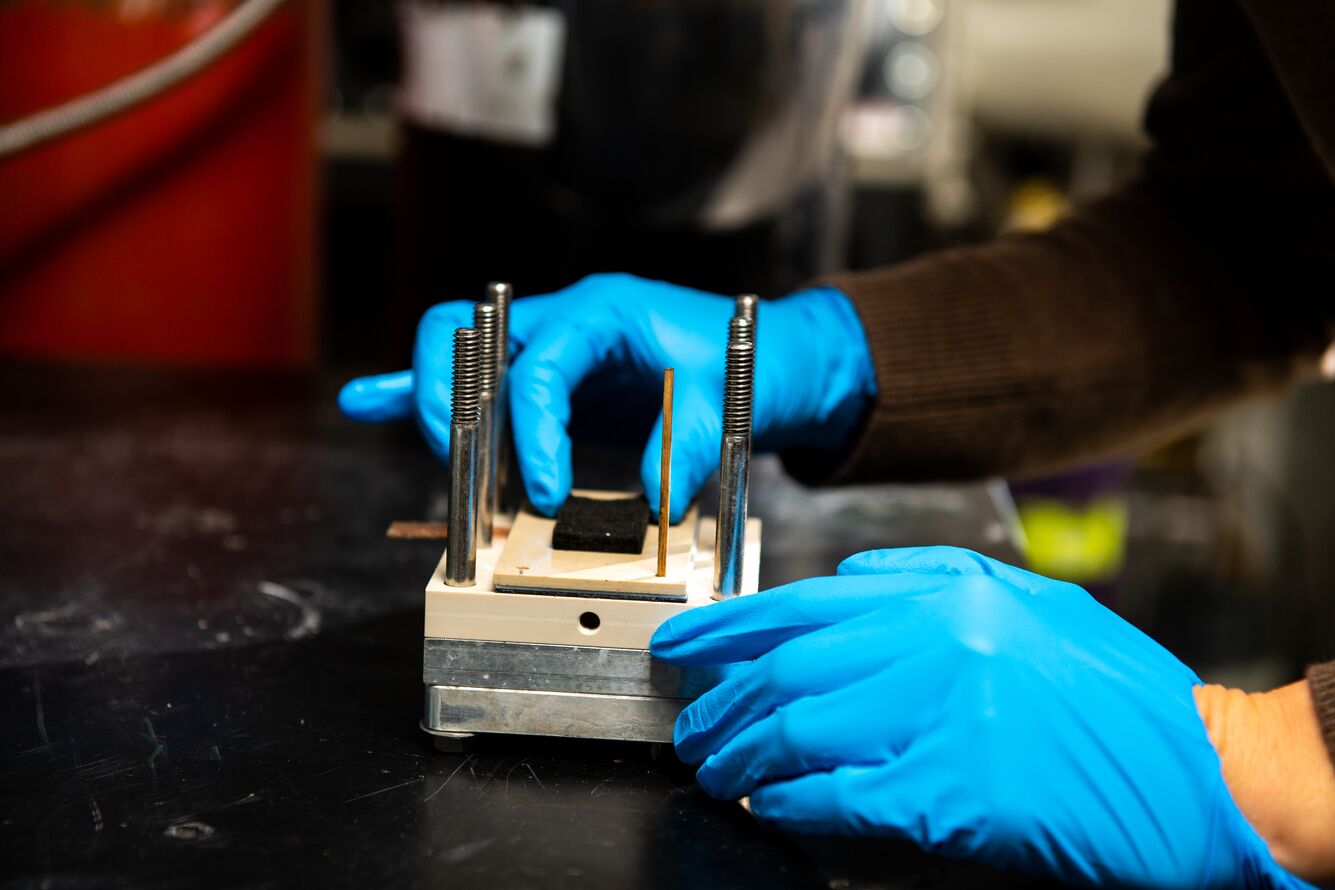

A Flow cell for conversion

CleanSET is a patent-pending electrochemical technology where unrefined biocrude and wastewater can be fed directly from an HTL output.

The biocrude and wastewater flow through a cell, where they encounter a charged environment created by an electric current. The flow cell is divided in half—with a positively charged anode and a negatively charged cathode. Both sides are separated by a membrane.

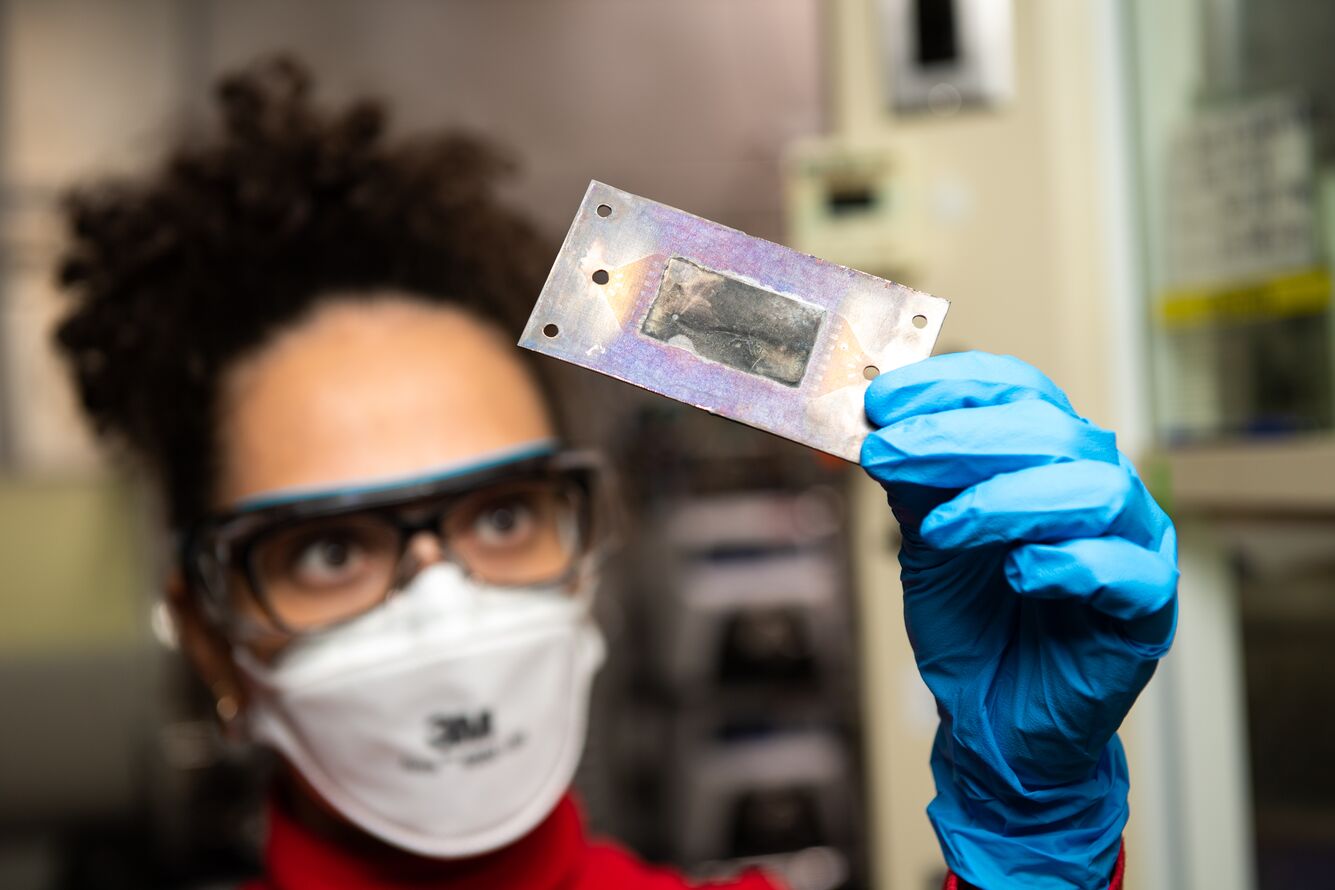

The anode contains a thin titanium foil catalyst coated with ruthenium oxide nanoparticles. The biocrude is converted to useful oils and paraffin while the contaminants in the wastewater are mainly converted to volatile hydrocarbons (e.g., ethane, propane, butane) as well as nitrogen and oxygen gasses. The treated wastewater emerging from the process is then organic-contaminant-free and can be reused as process water or reclaimed for other useful purposes, such as irrigation.

In the cathode, a different reaction occurs. Either the organic molecules are hydrogenated or hydrogen gas is generated, which can then be captured and used as supplemental fuel to reduce energy costs.

On-site energy production

The modular technology allows for onsite processing with little maintenance. CleanSET also performs chemical conversion more quickly than systems using energy-intensive high-temperature processes. The inventors obtained more than 100 times higher conversion rates with this electrochemical system at atmospheric conditions than those typically achievable with thermal conversion systems at intermediate hydrogen pressures and temperatures.

Another benefit of this system is that it requires 1,000 times less costly precious metals, such as ruthenium, than what is typically required for catalytic conversion. The lab-scale CleanSET uses 5 to 15 milligrams of ruthenium versus 10 grams of platinum for conversion in typical systems.

The CleanSET system can handle processing of small water-soluble carbon compounds, byproducts found in the water waste streams of current biomass conversion and industrial processes. About a dozen of these compounds exist in low concentrations in wastewater streams, making purification and concentration not cost-effective. Thus, carbon compounds like propanoic acid and butanoic acid are transformed to fuels like ethane, propane, hexane, and hydrogen during the CleanSET process.

The electricity cost required to operate the system can be offset by running the system at low voltage and either using the gaseous products (i.e., propane, butane, and excess hydrogen) to generate heat and power on site or selling the excess hydrogen for industrial use.

Industry applications

CleanSET, available for licensing, can benefit many industries, including bioenergy companies, wineries, municipal wastewater treatment plants, dairy farms, breweries, chemical manufacturers, and food and beverage producers.

This technology can be used to treat bio-oils and wastewater, or wastewater itself. These industries can renewably convert wastewater into hydrogen and valuable chemical intermediates--extracting value from waste streams that otherwise would be costly to treat, while also benefiting from reuse of the cleaned wastewater.

Advantages

- Conversion rates are 100 times higher than thermal systems.

- Modular technology allows for on-site processing, with little maintenance.

- Hydrogen generated from the process can be used for powering cars and heating.

- Removes harmful contaminants and converts them to hydrogen and biogas for energy use.

- Allows wastewater to be purified and reused, reducing costs for water consumption and treatment.

- Energy-efficient process using room temperature, assuring sustainability of the environment and reducing energy consumption.

- Requires 1,000 times less costly precious metals for conversion.